Electricity Distribution

Environmentally Friendly Distribution Poles

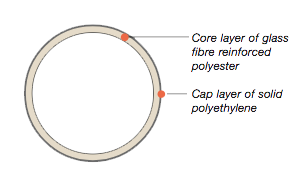

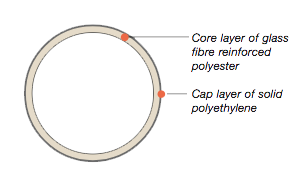

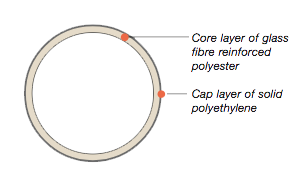

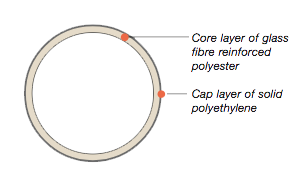

Our poles are made from fibreglass reinforced polyester, completely covered in a solid 3-4mm shell of dyed polyethylene. The inner layer has a high resistance to chemicals, moisture, vermin and pests, as well as physical impact.

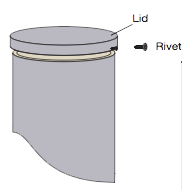

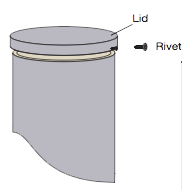

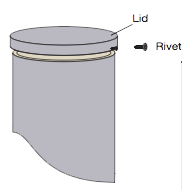

Before leaving the factory, poles are fitted with a cap to keep water and moisture from entering.

Product Data Sheet PDF

Construction

Our poles are made from fibreglass reinforced polyester, completely covered in a solid 3-4mm shell of dyed polyethylene.

The inner layer has a high resistance to chemicals, moisture, vermin and pests, as well as physical impact.

Length

Poles are manufactured in all standard lengths up to 16m. Longer lengths are available on request.

Weight

Each pole is considerably lighter than the corresponding wooden equivalent. A Jerol G12 for example, is approximately 200kg and a Jerol E16 approximately 400kg.

Diameter

The diameter of our composite poles is virtually the same from top to bottom. The diameter can vary depending on the pole length and load requirements. Poles with lower load requirements have an approximate diameter of 215mm and those with higher requirements an approximate diameter of 265mm.

Thickness

The wall thickness varies from 10-25mm depending on the length and load requirements of the pole.

Climbing

Jerol poles are climbed using the same equipment as wooden poles. See film: climbing.

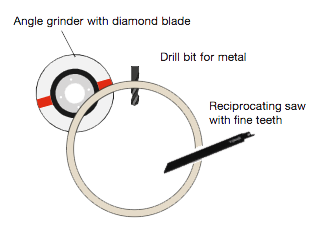

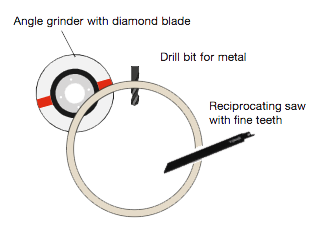

Cutting

A standard angle grinder with a diamond cutting disc can be used, or alternatively, a reciprocating saw with a fine-toothed blade. Fibreglass dust can irritate the skin so the appropriate protective equipment should be used. Chainsaws should not be used, as the composite material interferes with the chain. See film: cutting.

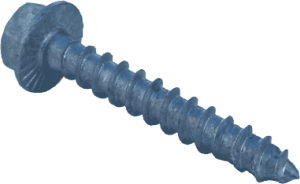

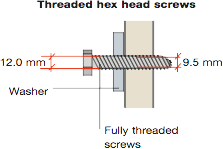

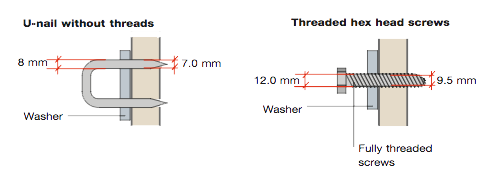

Hex Head Screws

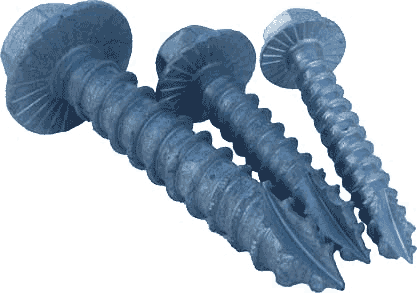

Predrilled holes are required and hex head screws are to be used. Holes should be drilled with a diameter of 0.5-1.0mm less than the thread diameter of the screw (see illustration). Self drilling screws with a coarse thread can be used.

Mounting Equipment

Hex head screws should be used in a predrilled hole. Our recommendations for hole and screw diameters should be followed. See film: mounting equipment.

Self-drilling screws with a coarse thread may also be used. See film: mounting a sign.

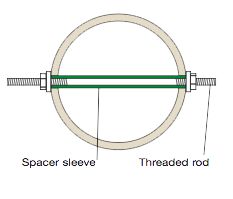

Mounting Points

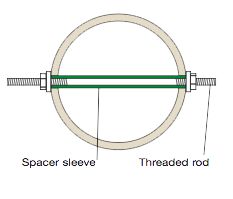

A spacer sleeve should always be used alongside a threaded rod. See film: mounting a spacer sleeve.

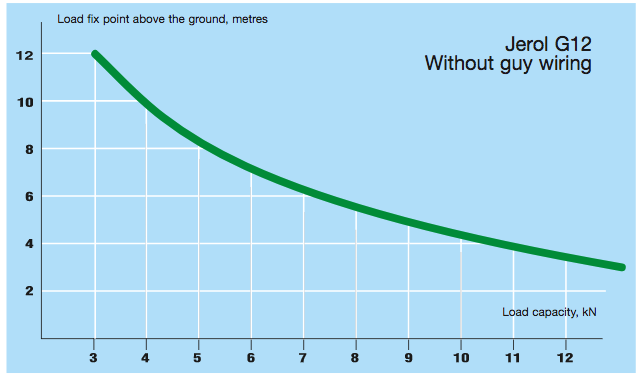

Load Capacity

A Jerol G12 composite pole has the same load capacity as the equivalent G12 wooden pole.

Guy-Wires

Guy-wires can be mounted using the same methods used for wooden poles.

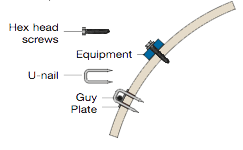

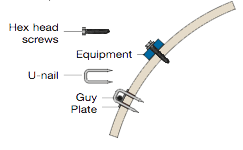

Guy-Wires with U-Nails

If guy-wires are to be attached with U-nails, a predrilled hole is required. To ensure secure attachment, the diameter of the hole should be 1mm less than the staple. See video: guy wiring with U-nails.

When installing in mountainous terrain, a regular strut pole bracket can be used

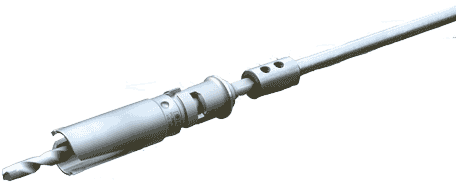

Raising Composite Poles

Poles are raised with “Grab John” in a similar way to wooden poles. Poles should not be lifted from the top, rather the best location is from the centre of the pole. See film: raising a composite pole.

Grab John should be used with care, as too much pressure can damage the pole. Poles should be transported with caution, as the stress on poles can quickly increase large in rough terrain.

Together with Huddig, Jerol has developed a pressure distribution device for Grab John jaws which is perfect to use when moving and erecting Jerol composite poles. The picture to the right shows this pressure distribution equipment mounted on Grab John jaws.

Pole Caps

All poles are fitted with a cap before leaving the factory.

Pole Bases

Poles are fitted with a base to prevent them from sinking in soft earth.

Year Marker

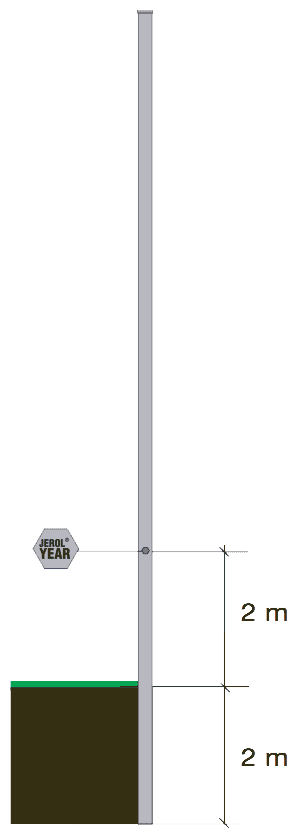

Every pole is fitted with Jerols trademark, product type, and year of production. This is mounted 4m from the bottom of the pole.

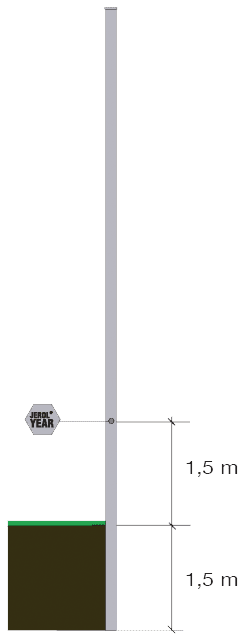

Installation Depth

This is the same depth used for wooden poles, i.e. 2m. Similarly, our products are buried using the same method used for wooden poles.

Height Adjustment

To ensure that the year marker is 2m from the ground, a pole may require cutting. Cutting can be performed with an angle grinder or reciprocating saw.

Installation in Mountainous Terrain

Poles are easily installed in mountainous terrain using rock dowels and hex head screws. See video: installation with a rock dowel

Storage and Waste Disposal

There are no special requirements when storing Jerol products as they are completely non-toxic. Dismantled posts can be reused, and smaller sections work well as cable protection. Damaged sections can be recycled or responsibly disposed of in landfill.

Occupational Health & Safety

General safety precautions for machining must be followed. Our products are non-toxic, and the material safety data sheet (MSDS) can be found here (Swedish).

Pole Classification

Distribution poles are named according to their load capacity and class, in the same method used for wooden poles. The classes N,G, E, S and S+2 are used, and the length is given in metres.

The example shown on the right is a Jerol G12, i.e. a 12 metre, type G pole. When buried correctly in a 2m deep hole, the pole will stand 10m above the ground. At 0.2m from the top, the pole has a load capacity of 4.3kN

Preparation and Dimensioning

The same methods for wooden poles can be used.

Transport

Poles can be transported alongside other goods and there are no special requirements when storing.

Lifespan

Our poles have a calculated lifespan of more than 80 years, this is based on 50 years practical experience of composite poles in corresponding climates.

Environment

Jerol products are the perfect alternative when the installation of creosote impregnated posts is prohibited, according to EU REACH legislation: “… in playgrounds, parks, gardens and outdoor recreation facilities where there is risk of frequent contact with the skin.” (REACH Chap. 31, Appendix XVII, Regulation (EC) No 1907/2006.)

Reference Project

Our composite distribution poles have been installed since 2009 and can be found in grid networks throughout the Nordic region. You can see more in our Reference Project.

Installation Video

The video to the right shows the installation of a composite pole in mountainous terrain using rock dowels.

Transmission Poles

Transmission Poles

Jerol transmission poles are suitable for overhead lines in the voltage range 45kV-132kV. Jerol composite poles can be assembled as H-frames and are designed to withstand exceptional loads and weather conditions.

Reference Project

Jerol transmission poles have been tested and installed with great results. See more in our Reference Project.

Meter Box Poles

Meter Box Poles

Jerol meter box poles are made from fibreglass reinforced polyester and covered by a solid 3mm shell of polyethylene. This protects from weather and UV-damage and results in an odourless and non-greasy product.

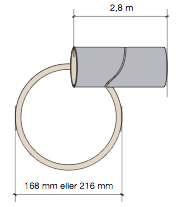

Length, Weight and Diameter

Poles are produced in lengths of 2m, 3m, and 4m. Larger sizes are available upon request.

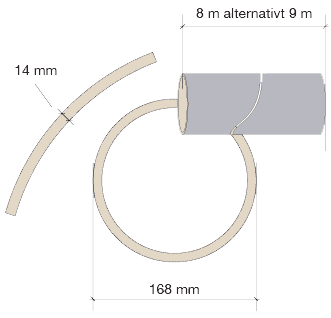

The poles are available in two diameters, 168mm and 216mm. The 216mm post can also be used for the suspension of transformers.

Installation

Poles can be installed without the need for a foundation.

Product Data Sheet PDF

Construction

Jerol meter box poles are made from fibreglass reinforced polyester and covered by a solid 3mm shell of polyethylene. This protects from weather and UV-damage and results in an odourless and non-greasy product.

This combination of materials has a high resistance to chemicals, moisture, vermin and pests, as well as physical impact. Poles are fitted with a cap to prevent water and moisture from entering.

Length, Weight and Diameter

Poles are produced in lengths of 2m, 3m, and 4m. Larger sizes are available upon request.

The poles are available in two diameters, 168mm and 216mm. The 216mm pole can also be used for the suspension of transformers.

Installation

Poles can be installed without the need for a foundation.

Mounting the Meter Box

The meter box is attached with screws into predrilled screw holes. Alternatively, self-drilling screws with a course thread can also be used. A transformer bracket is installed using fully threaded hex head screws or a pin bolt.

Predrilling should be performed with the appropriate drill, and pin bolts should not be used without a distance sleeve.

See also the product sheet for Jerol Distribution Poles.

Pole Cap

Poles are fitted with a cap before leaving the factory.

Storage and Handling

There are no special requirements when storing Jerol products as they are completely non-toxic. Dismantled poles can be reused, and smaller sections work well as cable protection. Damaged sections can be recycled or responsibly disposed of in landfill.

Occupational Health & Safety

Our products are non-toxic, and general safety precautions must be followed. See also the material safety data sheet (MSDS).

Transport

Poles can be transported alongside other goods, and there are no special requirements for storage.

Environmental Impact

Our products are non-toxic, non-greasy, and do not leach chemicals. This makes them the perfect choice for installation in environmentally sensitive areas.

Lifespan

Our poles have a calculated lifespan of more than 80 years, this is based on 50 years practical experience of composite poles in corresponding climates.

Reference Project

Meter boxes are often placed near buildings, where it is particularly important to have non-toxic and non-greasy poles. See more in our Reference Project.

Cable Ducts

Cable Ducts

Our environmentally friendly cable ducts are used to carry and protect cables over streams and dikes without impacting the environment.

Order through a wholesaler or ring us directly.

Cable Ducts PDF

Construction

Jerol cable ducts are clean and odourless composite posts made from fibreglass reinforced polyester. A 3mm thick shell of solid polyethylene covers the entire outside of the post and protects it from weather and UV-damage.

This combination of materials has a high resistance to chemicals, moisture, vermin and pests, as well as physical impact.

Length and Dimensions

Ducts are produced in lengths from 4-14m. Other lengths are available on request.

The ducts are available in three different inner-diameters, Ø140 mm, Ø190mm and Ø240 mm.

Installation

Our environmentally friendly cable duct is used to carry and protect cables over streams and dikes without impacting the environment.

Longevity

Ducts do not impact nor are affected by the environment, in addition to retaining their positive qualities over a long lifespan.

Occupational Health & Safety

Our products are non-toxic, and general safety precautions must be followed. See also the material safety data sheet (MSDS) in chapter 11: Environmental Aspects, of the Jerol Handbook.

Storage and Handling

There are no special requirements when storing Jerol products as they are completely non-toxic. Dismantled products can be reused and damaged sections can be recycled or responsibly disposed of in landfill.

Transport

Poles can be transported alongside other goods.

Environmental Impact

Our products are non-toxic, non-greasy and do not leach. This makes them the perfect choice for installation in environmentally sensitive areas.

Lifespan

Our poles have a calculated lifespan of more than 80 years, this is based on 50 years practical experience of composite poles in corresponding climates.

Reference Project

Jerol poles make excellent cable ducts, see more in our Reference Project.

Telecommunication Poles

Composite Telecommunication Poles

Composite telecommunication poles are the safe and reliable choice. We are committed to producing an environmentally friendly product, without compromising on the best possible working conditions. The poles are completely non-toxic, lightweight and easy to work with. Our poles have a calculated lifespan of 80 years and are maintenance free, making than an excellent investment.

Product Data Sheet PDF

Construction

Jerol poles are made from fibreglass reinforced polyester. A 3mm thick shell of solid polyethylene covers the entire outside of the post and protects it from weather and UV-damage.

Dimensions

Pole length: 8m and 9m

Outer diameter: 166-172mm

Fibreglass thickness: 11mm +1/-0.5

Polyethylene shell: 3mm

Weight

An 8m pole weights 100kg and a 9m pole weighs 110kg

Cutting

A standard angle grinder with a diamond cutting disc can be used, or alternatively, a reciprocating saw with a fine-toothed blade. Fibreglass dust can irritate the skin so the appropriate protective equipment should be used. Chainsaws should not be used, as the composite material interferes with the chain.

See film; cutting.

Guy-Wires

If required, guy-wires are attached with U-nails as shown. U-nails require a predrilled hole with a diameter 1mm less than the nail to ensure a secure attachment.

See film; mounting with U-nails.

Brace kit: e-number: 0600014

Drill: We recommend a Wedevåg 5mm Futara bit for drilling.

Nails require a predrilled hole with a diameter 1mm less than the nail to ensure a secure attachment.

Fixings & Fastenings

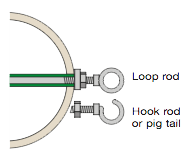

Fixings and fastenings are mounted with a fully threaded hex head screw. A 10mm screw is to be used with a 6mm hole.

Mounting Eye Screws

Holes should be predrilled with a diameter matching that of the screw’s core diameter. A 6mm hole will usually suffice.

Mounting Signs

Self-drilling screws or blind rivets should be used when mounting signs.

Mounting Cleats

A predrilled hole with a diameter 1mm less than the cleat diameter is required. A 5mm hole will usually suffice.

Installating Mountainous Terrain

When installing poles on mountains, a standard rock dowel or rock anchor can be used. The base of the pole has a hole for use with a rock anchor.

Raising a Composite Pole

Poles are raised using the same method as wooden poles.

Pole Caps

Poles are fitted with a cap before leaving the factory.

Pole Bases

Poles are fitted with a base to prevent them from sinking in soft earth.

Year Marker

Every pole is fitted with Jerols trademark, product type and year of production. This is mounted 3m from the bottom of the pole.

Repairing a Damaged Pole

In the eventuality of surface damage, from a lawn mower for example, repair the pole using Vulkduk. Damage to the fibreglass core requires an inspection to determine whether the pole can be repaired or replaced.

Technical Information for Vulkduk:

Vulkduk Nitto 57GO/c, 150mm x 19m

MPPA 14801/1

Telia E-Number 07 552 15

Climbing and Safety

Material Safety Data Sheet

Reference Project

Jerol telecommunication poles have been installed by Skanova, amongst others. See more in our Reference Project.

Composite Anchors

Composite Anchor with Stud Bolt and Plate

Composite anchors are made from fibreglass reinforced polyester, with a 3-4mm shell of dyed polyethylene.

The inner layer has a high resistance to chemicals, moisture, vermin and pests, as well as physical impact.

Product Data Sheet PDF

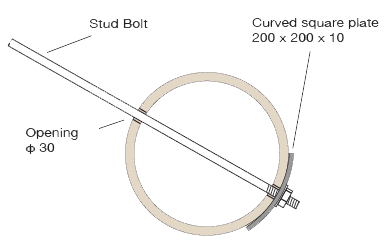

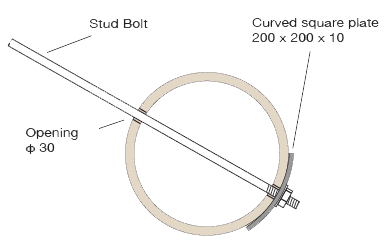

Construction

Composite anchors are made from fibreglass reinforced polyester, completely covered in a 3-4mm thick shell of dyed polyethylene.

The inner layer has a high resistance to chemicals, moisture, vermin and pests, as well as physical impact.

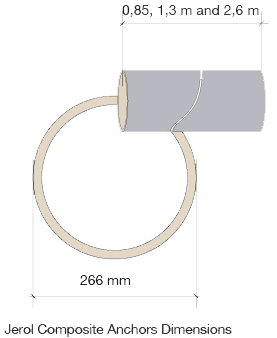

Length

Composite anchors are produced in the following lengths: 0.85m, 1.3m and 2.6m. Other lengths available on request.

Weight

The 0.85m composite anchor weighs approx. 15-30kg, the 1.3m approx. 20-25kg, and the 2.6m approx. 40-50kg. A lower weight makes installation quick and easy.

Load Capacity

The breaking load of the composite anchor is approximately 100kN when coupled with the stud bolt and curved plate.

Installation Depth

Burial and retrieval of the product is carried out using the standard method.

Stud Bolt

A curved square plate (200x200x10mm) is used when affixing the stud bolt.

Environment

Jerol products are the perfect alternative when the installation of creosote impregnated posts is prohibited, according to EU REACH legislation: “… in playgrounds, parks, gardens and outdoor recreation facilities where there is risk of frequent contact with the skin.”

(REACH Chap. 31, Appendix XVII, Regulation (EC) No 1907/2006.)